Products

-

Best popular JKR35 Mud Soil Clay Brick Machine

Red brick machine, vacuum extruder, using a single extrusion principle, using a motor, through the axial pneumatic clutch through the reducer split drive superior mixing and lower extrusion part synchronous. Compact structure, energy saving effect is obvious.

-

JKY40 Automatic Brick Making Machine

Jky series double stage vacuum extruder is our factory designed and manufactured new brick manufacturing equipment through advanced domestic and international experience. The double stage vacuum extruder is mainly used for the raw materials of coal gangue, coal ash, shale and clay. It is the ideal equipment for producing all kinds of standard brick, hollow brick, irregular brick and perforated brick.

Our brick machine has strong applicability, compact structure, lower energy consumption and higher production capacity.

-

High production capacity Double Shaft Mixer

The Double Shaft Mixer Machine is used for grinding brick raw materials and mixing with water to get uniform mixed materials, which can further improve the performance of raw materials and greatly improve the appearance and molding rate of bricks. This product is suitable for clay, shale, gangue, fly ash and other extensive working materials.

-

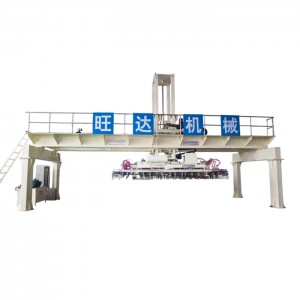

Automatic Pneumatic Brick Stacking Machine

Automatic stacking machine & stacking robot are new brick automatic stacking, replace manual stacking way. It can greatly improve stacking efficiency and reduce labor cost. Depending on the size of the kiln, we should choose different types of stacking machine & stacking robot.

-

JZ250 Clay Mud Soil Brick Extruder

Jkb50/45-3.0 automatic clay brick machine is suitable for all shapes and sizes of solid brick, hollow brick, porous brick and other clay products. Also suitable for a variety of raw materials. It is characterized by novel structure, advanced technology, high extrusion pressure, high output and high vacuum. Pneumatic clutch control, sensitive, convenient and reliable.

-

WD1-15 Hydraulic brick pressing machine

WD1-15 Hydraulic Interlocking Brick Making Machine is our newest clay and cement brick making machine.it is semi-automatic operation machine.its material feeding.mould pressing and mould lifting automatically ,you can chose diesel engine or motor for power supply.

The most versatile of the market, for enable varied models of blocks, bricks and floors in only one equipment, without the need of buy another machine.It is hydraulic pressure,easy operation.about 2000-2500 Bricks a day.The best choice for small factory to bulid small clay plant.diesel enginee or motor for your choose.

-

High Efficiency Energy Saving Automatic Tunnel Kiln

Our company has tunnel kiln brick factory construction experience at home and abroad. The basic situation of the brick factory is as follows:

1. Raw materials: soft shale + coal gangue

2. Kiln body size :110mx23mx3.2m, inner width 3.6m; Two fire kilns and one dry kiln.

3. Daily capacity: 250,000-300,000 pieces/day (Chinese standard brick size 240x115x53mm)

4. Fuel for local factories: coal

-

WD2-15 Interlocking ECO Brick Making Machine

WD2-15 Hydraulic Interlocking Brick Making Machine is our newest clay and cement brick making machine.it is semi-automatic operation machine.its material feeding.mould pressing and mould lifting automatically ,you can chose diesel engine or motor for power supply.

The most versatile of the market, for enable varied models of blocks, bricks and floors in only one equipment, without the need of buy another machine.It is hydraulic pressure,easy operation.about 4000-5000 Bricks a day.The best choice for small factory to bulid small clay plant.diesel enginee or motor for your choose.

-

WD4-10 Interlocking Brick Making Machine

1. Fully automatic clay cement brick machine. PLC controller.

2. It is equipped with a belt conveyor and a cement clay mixer.

3. You can make 4 bricks each time.

4. Be deeply praised by domestic and foreign customers.

-

JKB5045 Automatic Vacuum Brick Extruder

Jkb50/45-3.0 automatic clay brick machine is suitable for all shapes and sizes of solid brick, hollow brick, porous brick and other clay products. Also suitable for a variety of raw materials. It is characterized by novel structure, advanced technology, high extrusion pressure, high output and high vacuum. Pneumatic clutch control, sensitive, convenient and reliable.

-

WD2-40 Manual Interlock Brick Machine

1.Easy Operation. This machine can be operated by any workers just by short-time leaning

2 .High-efficiency. With low consumption of material,every brick can be made in 30-40s,which will ensure a quick production and good quality.

3.Flexibility. WD2-40 is with a small body size,so it can cover less land area.Moreover, it can be moved from one to another place easily. -

Hoffman kiln for firing and drying clay bricks

The Hoffmann kiln refers to a continuous kiln with an annular tunnel structure, divided into preheating, bonding, cooling along the length of the tunnel. When firing, the green body is fixed to one portion, sequentially add the fuel to the various locations of the tunnel, so that the flame is continuously moved forward, and the body is sequentially passed through three stages. The thermal efficiency is high, but the operating conditions are poor, used for firing bricks, watts, coarse ceramics and clay refractories.